Oil & Gas

As a supplier of catalyst and process technology, Applied Catalysts can help customers source catalysts and chemicals in many areas.

NSPS & Tier 4 Catalyst Solutions

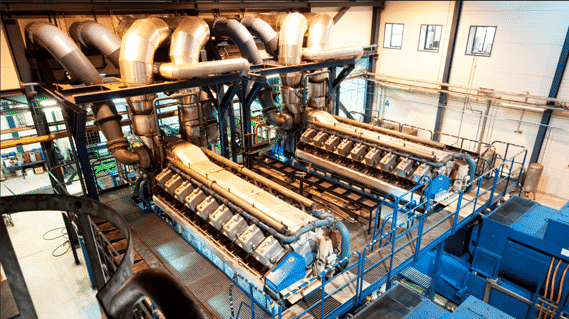

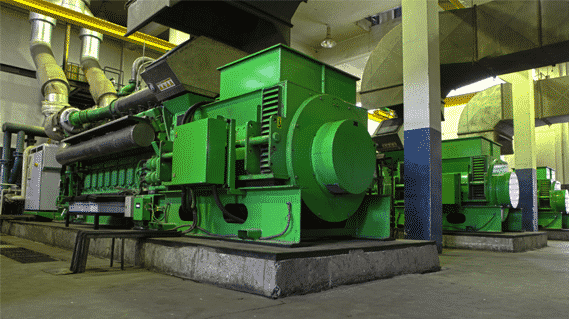

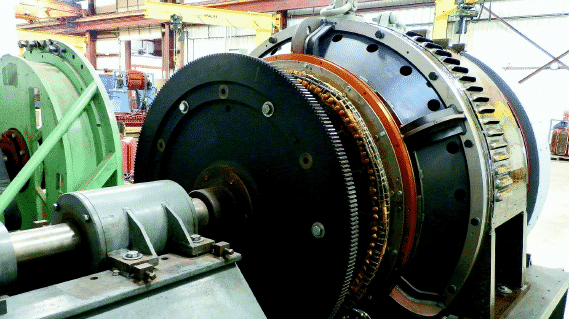

When it comes to Power Generation via Spark Ignited or Compression Ignition engines, trying to figure out the various EPA rules to maintain compliance can be very complicated. Also the types of devices used to meet these regulations can be different depending on the engine tuning, type of fuel and strategy of the end user. NESHAP, NSPS, RICE, Tier 4 Interim versus Tier 4 Final, what do all these acronyms mean?

- A great deal of information can be found here: https://www.epa.gov/stationary-engines

- RICE – Reciprocating Internal Combustion Engine

- NESHAP – National Emission Standard for Hazardous Air Pollutants

- CFR Title 40> Chapter 1 > Subchapter C > Part 63 > Subpart ZZZZ

- NSPS – New Source Performance Standards. There are two rules for this, one for Spark Ignited and one for Compression Ignition engines.

- CFR Title 40 > Part 60 > Subpart JJJJ

What is Tier 4?

Tier 4 is an EPA rule designed to reduce harmful exhaust gases for diesel powered equipment. Tier 4 standards require significant emission reductions of particulate matter (PM) and Nitrogen Oxides (NOx). PM is defined as the black smoke/soot found in engine diesel engine exhaust, and NOx is defined as nitrogen monoxide and nitrogen dioxide. The table below shows the Tier 4 Final emission limits by pollutant type.

Tier 4 Final Emission Limits by Pollutant

Pollutant |

Tier 4 Final (g/bhp-hr) |

| Hydrocarbons (HC) | 0.14 |

| Nitrogen Oxides (NOx) | 0.3 |

| Carbon Monoxide (CO) | 2.2 |

| Particulate Matter (PM) | 0.015 |

What do all these EPA rules mean? Depending on the engine size, the duty cycle, the fuel type and the targeted regulation, the solution may be a lean burn oxidation catalyst, an NSCR (non-selective catalytic reduction or 3-way) catalyst, a Diesel Oxidation Catalyst, a Diesel Particulate Filter, and SCR Catalysts (selective catalytic reduction via use of urea as reductant).

Bring Us Your Challenge

Product Types for Emission Control

Activated Carbon Monolith

In chemical process applications, ACMC® catalysts can be used for continuous hydrogenation reactions in many areas where traditional GACC (granular activated carbon catalysts) are currently used.

Monolithic Catalysts

Our monolithic solutions include activated carbon, ceramic, and metallic catalysts that have great applications for engine emissions control and industrial air pollution.

Particulate Systems

Our particulate systems include extrudates, precious metal spheres and saddles for regenerative air pollution control. Enjoy benefits like 95% heat recovery.

RTO/RCO Media

We offer unique designs, such as our ceramic honeycomb, that provides excellent benefits including high resistance to thermal shock and solid thermal mass for effective heat exchange.

Market Applications for Emission Control

DON’T SEE YOUR APPLICATION?

Have another market application needing a catalytic system? Tell us about it, and let’s create something that gets the job done.

Partner with the best for Emissions Control Catalysts & Services

Applied Catalysts works with many suppliers across the globe. We can provide the following:

-

in-house validation capabilities

-

in-house and external catalyst supplier

-

connections with many manufacturers

Bring Us Your Challenge