Ceramic Monoliths

As a supplier of catalyst and process technology, Applied Catalysts can help customers source catalysts and chemicals in many areas.

Ceramic Monoliths for Air Pollution Control

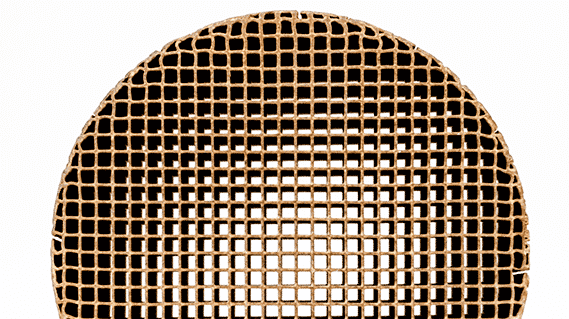

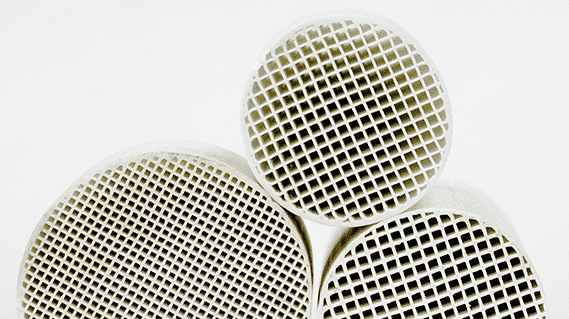

Applied Catalysts manufactures a wide variety of ABATE VOC™ ceramic monolith supported catalysts. Monolithic catalyst supports are honeycomb structures with many small “cells”, or parallel channels that allow exhaust gases to run axially through the catalyst. Monoliths are sometimes called “flow-through” substrates. Exhaust gases flowing through the cells contact the catalyst surface which has been coated onto the cell walls.

The major advantages of monolithic supports include high geometric surface area (GSA) per unit volume (small compact design for a catalytic oxidizer), large open frontal area (low pressure drop), and excellent attrition resistance (robust design). A major advantage of Applied Catalysts is that we obtain the majority of our ceramic supports in house, via Applied Ceramics Inc. (www.appliedceramics.com). The VersaGrid™ ceramic monoliths are manufactured in a wide variety of cell densities or geometries, including but not limited to 16, 25, 50, 64, 100, 200, 230, and 400 cpsi (cells per square inch), so Applied Catalysts can design your catalyst to meet your specific needs.

Depending on your application, Applied Catalysts can also use Metal Monolith Supports for your catalyst needs.

Bring Us Your Challenge

Product Types for Emission Control

Activated Carbon Monolith

In chemical process applications, ACMC® catalysts can be used for continuous hydrogenation reactions in many areas where traditional GACC (granular activated carbon catalysts) are currently used.

Monolithic Catalysts

Our monolithic solutions include activated carbon, ceramic, and metallic catalysts that have great applications for engine emissions control and industrial air pollution.

Particulate Systems

Our particulate systems include extrudates, precious metal spheres and saddles for regenerative air pollution control. Enjoy benefits like 95% heat recovery.

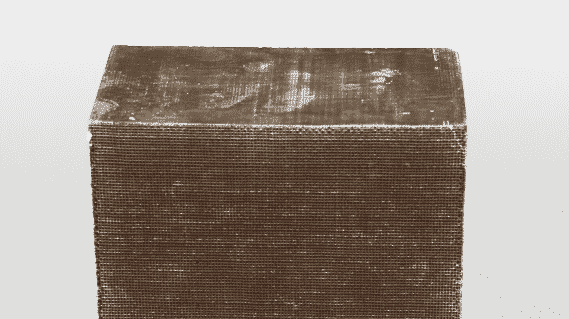

RTO/RCO Media

We offer unique designs, such as our ceramic honeycomb, that provides excellent benefits including high resistance to thermal shock and solid thermal mass for effective heat exchange.

Market Applications for Emission Control

DON’T SEE YOUR APPLICATION?

Have another market application needing a catalytic system? Tell us about it, and let’s create something that gets the job done.

Partner with the best for Emissions Control Catalysts & Services

Applied Catalysts works with many suppliers across the globe. We can provide the following:

-

in-house validation capabilities

-

in-house and external catalyst supplier

-

connections with many manufacturers

Bring Us Your Challenge