Catalytic Oxidation

As a supplier of catalyst and process technology, Applied Catalysts can help customers source catalysts and chemicals in many areas.

Catalysts for Catalytic Oxidation

What is a catalyst? A catalyst is a substance that lowers the activation energy for a given reaction. When trying to oxidize hydrocarbons, carbon monoxide or VOC’s, the activation energy required for the combustion reaction is “Heat”. So in the case of catalytic oxidation, the amount of heat (activation energy) required to abate targeted compounds is lowered dramatically, compared to thermal oxidation.

To illustrate the power of catalysts, let’s look at the oxidation of formaldehyde:

CH2O + O2 → CO2 + H2O

Simple on paper, the oxidation of formaldehyde is quite difficult thermally, requiring temperatures in excess of 1500°F. Using a catalyst, this reaction can take place at less than 600°F. So as this example illustrates, the operating costs for a catalytic oxidation system can be 40 – 60% lower than with thermal oxidation.

Important design factors for catalytic oxidation include temperature (an operating temperature high enough to oxidize the target compounds across the catalyst), residence time (sufficient residence time in the catalyst bed for the oxidation reaction to occur – commonly referred to as Space Velocity or GHSV), turbulence or mixing of combustion air with the targeted compounds, the VOC concentration and species, catalyst characteristics, and the presence of masking agents in the effluent stream that can potentially reduce the effectiveness of the catalyst bed.

Many types and styles of oxidation catalyst are used in catalytic oxidation. Depending on the application or style of catalytic oxidizer to be employed, ceramic or metal monolith, spheres, extrusions, or RCO Catalysts may be the best fit for a given application. Contact Applied Catalysts to find out more.

Bring Us Your Challenge

Product Types for Emission Control

Activated Carbon Monolith

In chemical process applications, ACMC® catalysts can be used for continuous hydrogenation reactions in many areas where traditional GACC (granular activated carbon catalysts) are currently used.

Monolithic Catalysts

Our monolithic solutions include activated carbon, ceramic, and metallic catalysts that have great applications for engine emissions control and industrial air pollution.

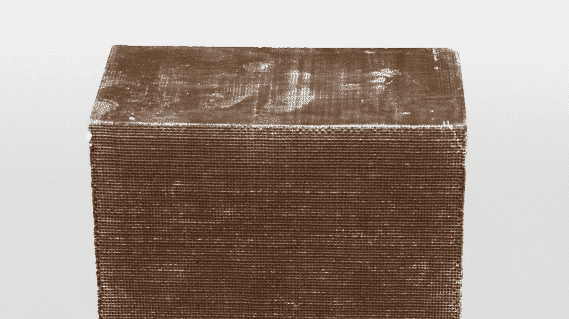

Particulate Systems

Our particulate systems include extrudates, precious metal spheres and saddles for regenerative air pollution control. Enjoy benefits like 95% heat recovery.

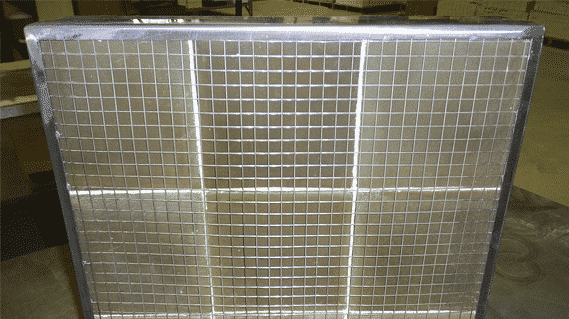

RTO/RCO Media

We offer unique designs, such as our ceramic honeycomb, that provides excellent benefits including high resistance to thermal shock and solid thermal mass for effective heat exchange.

Market Applications for Emission Control

DON’T SEE YOUR APPLICATION?

Have another market application needing a catalytic system? Tell us about it, and let’s create something that gets the job done.

Partner with the best for Emissions Control Catalysts & Services

Applied Catalysts works with many suppliers across the globe. We can provide the following:

-

in-house validation capabilities

-

in-house and external catalyst supplier

-

connections with many manufacturers

Bring Us Your Challenge