Odor & Smoke Elimination

As a supplier of catalyst and process technology, Applied Catalysts can help customers source catalysts and chemicals in many areas.

Odor & Smoke Oxidation Catalysts

Nuisance odors can pose a problem for employees and neighbors alike, as even in very low quantities (ppb levels), some compounds such as sulfur containing mercaptans, and amine containing compounds are disturbing. Catalytic Oxidation can be used to eliminate even very low levels of odiferous compounds from processes such as food processing, meat smokehouses, animal rendering, as well as a variety of processes containing low levels of VOC’s such as architectural siding, printing, canning and laminating.

Smoke is a word used to describe a mixture of solid, liquid and gas particles. Smoke can contain hundreds of different chemicals and fumes, however most visible smoke is carbon (soot), tar, oils and ash. In complete combustion, everything is burned, producing just water and carbon dioxide. When incomplete combustion occurs, not everything is burned. Smoke is a collection of these tiny unburned particles. Each particle is too small to see with your eyes, but when they come together, you see them as smoke.

Bring Us Your Challenge

When there is incomplete combustion (not enough oxygen to burn a fuel completely), you get smoke. Sometimes smoke is created on purpose for example to “smoke meat”. Other times, the smoke is an undesirable by-product. In either case, release to the atmosphere may fall under local or state air regulations. Catalytic oxidation is often used to abate (oxidize) smoke. The most widely used application is with wood burning stoves. (see Applied Ceramics – www.firecatcombustors.com)

Another appliance application where smoke and odor is a problem is with Self-Cleaning Oven Smoke elimination. In self-cleaning ovens, during the “Self-clean” cycle, the inside of the oven is raised to temperatures in excess of 750°F. For safety reasons, this is why the door locks. At these high temperatures, any food or grease that has accumulated on the sides and bottom of the oven are combusted completely to smoke and odor (aerosols).

The appliance manufacture employs an oxidation catalyst, usually a small ceramic or a stainless steel screen, coated with precious metals such as platinum and palladium. These catalysts prevent the smoke and odor from filling the kitchen creating a health problem and nuisance, by catalytically combusting the smoke and odor to carbon dioxide and water. Applied Catalysts is the world leader for over 30 years in supplying millions of stoves with these specialty self-cleaning oven smoke eliminators.

Product Types for Emission Control

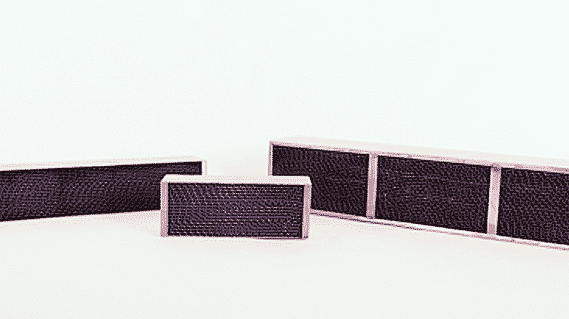

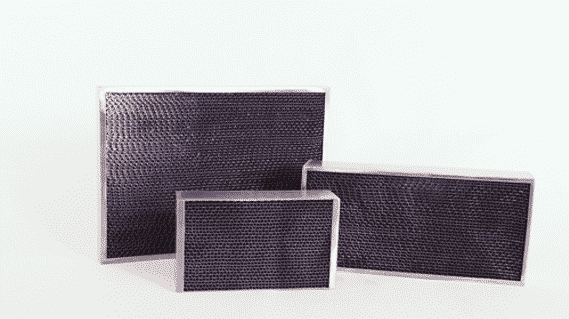

Activated Carbon Monolith

In chemical process applications, ACMC® catalysts can be used for continuous hydrogenation reactions in many areas where traditional GACC (granular activated carbon catalysts) are currently used.

Monolithic Catalysts

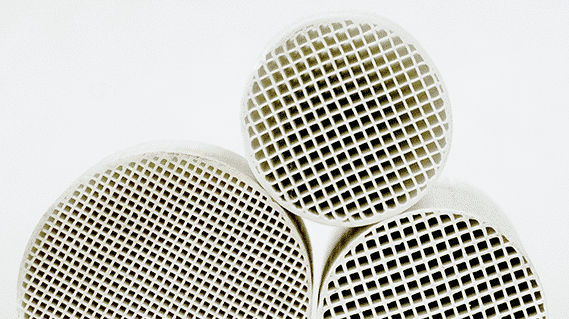

Our monolithic solutions include activated carbon, ceramic, and metallic catalysts that have great applications for engine emissions control and industrial air pollution.

Particulate Systems

Our particulate systems include extrudates, precious metal spheres and saddles for regenerative air pollution control. Enjoy benefits like 95% heat recovery.

RTO/RCO Media

We offer unique designs, such as our ceramic honeycomb, that provides excellent benefits including high resistance to thermal shock and solid thermal mass for effective heat exchange.

Market Applications for Emission Control

DON’T SEE YOUR APPLICATION?

Have another market application needing a catalytic system? Tell us about it, and let’s create something that gets the job done.

Partner with the best for Emissions Control Catalysts & Services

Applied Catalysts works with many suppliers across the globe. We can provide the following:

-

in-house validation capabilities

-

in-house and external catalyst supplier

-

connections with many manufacturers

Bring Us Your Challenge