Ozone Abatement

As a supplier of catalyst and process technology, Applied Catalysts can help customers source catalysts and chemicals in many areas.

Catalytic Ozone Abatement

Ozone (O3 ) is a form of oxygen that consists of three oxygen atoms joined together into a molecule. This form of oxygen has significantly different characteristics than the common oxygen molecule (O2), which consists of two oxygen atoms. The ordinary O2 form of oxygen is, of course, present in the air we breathe and is indeed necessary for life.

The role of ozone in the environment is more complex. First, ozone in the upper atmosphere is critical to protecting life on earth via the absorption of dangerous short wavelength UV from the sun. However, Ozone is harmful in the lower atmosphere since it is an irritant when breathed and is therefore an undesirable air pollution component.

Ozone is an unstable colorless gas with powerful oxidizing properties that will react with anything organic, and as a result is very corrosive. Ozone will also destroy any known bacteria and viruses and is used extensively for water treatment applications. Many other important industrial processes use or generate ozone. In order to maintain suitable air quality, the ozone content in air emitted from such industrial processes must be reduced to an acceptable concentration level before the air can be released into the environment. The EPA and OSHA both recommend that levels of Ozone be kept below 0.1 ppm in order to not adversely affect health.

In the printing industry ozone is typically formed in corona treaters and in the use of UV inks. Through the use of a special oxidation catalyst, the discharge of a corona treater can be directed to a catalytic oxidizer, and along with VOC emissions that might be present, the ozone will be completely destroyed by the process of combustion. No traces of ozone will be left. This method for ozone abatement has been successfully implemented for many printing applications.

A catalytic ozone abater can effectively decompose the ozone in the air that is fed to the passenger cabin of high flying commercial jet aircraft. Applied Catalysts has developed special oxidation catalysts that are very effective in eliminating ozone from the cabin air in passenger airplanes.

Regardless of the source, ozone should be eliminated for health concerns.

Bring Us Your Challenge

Product Types for Emission Control

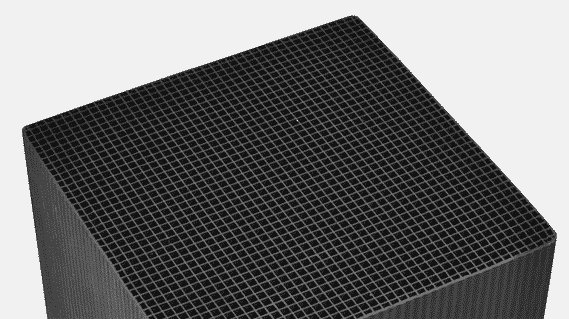

Activated Carbon Monolith

In chemical process applications, ACMC® catalysts can be used for continuous hydrogenation reactions in many areas where traditional GACC (granular activated carbon catalysts) are currently used.

Monolithic Catalysts

Our monolithic solutions include activated carbon, ceramic, and metallic catalysts that have great applications for engine emissions control and industrial air pollution.

Particulate Systems

Our particulate systems include extrudates, precious metal spheres and saddles for regenerative air pollution control. Enjoy benefits like 95% heat recovery.

RTO/RCO Media

We offer unique designs, such as our ceramic honeycomb, that provides excellent benefits including high resistance to thermal shock and solid thermal mass for effective heat exchange.

Market Applications for Emission Control

DON’T SEE YOUR APPLICATION?

Have another market application needing a catalytic system? Tell us about it, and let’s create something that gets the job done.

Partner with the best for Emissions Control Catalysts & Services

Applied Catalysts works with many suppliers across the globe. We can provide the following:

-

in-house validation capabilities

-

in-house and external catalyst supplier

-

connections with many manufacturers

Bring Us Your Challenge